| This

page is devoted to questions about the Franklin engines. Both the -B8F

and -B9F will be listed here. If you need manuals you can get them here. All questions will be listed forever; answered or not. |

Comments from members:

"Well Guys this

Q&A thing really works... Thanks a bunch"...Don Buck

| Questions |

Answers |

| Franklin Instation request... Steve, can you put a question out to the group soliciting any

information on franklin engine installation? Trying to ensure ours goes back in

correctly. Seems to be some differences with lord mounts specifically. We have

all 6 new old stock lord mounts but the rear mount did not have a spacer when

removed. I’ve seen one drawing of the rear with a spacer that has a rubber

bushing. Can’t seem to find any good detail on that and I know you looked for

me. Thanks! |

Answer... |

| Franklin rubber engine mounts... Our friends "downunder" need some help. If anyone knows thhe part number for the engine mount rubbers on a Daubenspeck conversion please email me at (smestler@comporium.net) or Steve Barlow at (SBarlow@airspeed.com.au). Thanks! |

Answer... P/N Barry Mounts, Part # 94110-40

Thanks to Chad Vanderhoof |

| Franklin Distributor Problem... Jaren Lynn has a problem with his Franklin. The left side is dead! Any idea what the problem is? contact Jaren and me at:

jlynnaviation@gmail.com and smestler@pbtcomm.net or both here |

Answer... In regard to Jaren's switch; The common mag switch is made to open

the circuit to unground a magneto and allow it to operate. Jaren needs a

switch that closes the circuit and allows power to flow to the coil on the

distributor side and opens the circuit on magneto side to unground the mag. I

can't think of a way to make a Gerdes or ACS mag switch do this.

Thanks to member Terry Matthews! |

|

Franklin Fuel pump plunger...

Tom Danaher has an inquiry about material for Franklin fuel pump diaphragms. A company called Rubber Sheet Roll (info@rubbersheetroll.com) of Shippensburg, PA, has fablic reenforced neprene available in 12" X 12" sheets .062 thick for $17.71. Now what I need to know is how does the fuel pump plunger attach to the cam

follower-rocker? And how do you take the diaphragm unit apart? (It's riveted

together.)

J. R. Ranney

|

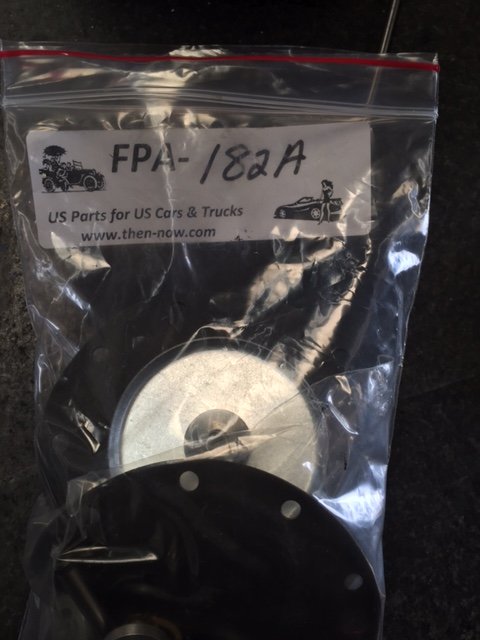

Finally, and answer to your Franklin Fuel Pump problems, maybe... (Ed note: As with any after market parts, no guarantee of results. Use at your own risk.) Memeber J.R. Ranney has the solution to your Franklin Fuel Pumps. His excellent write-up is here as well as information on Bruce Hind's December 2011 newsletter. You can contact JR at jwranny8@aol.com. JR writes: "Our Franklin fuel

pump problems are over! Thanks to Walter Windus, who discovered a source of

overhaul kits with all new parts, including the critical oil seal. It's a

company that specializes in parts for old cars and evidently there's one that

uses the same fuel pump as (our) the Franklin. The kits are $44.50 each plus

shipping as of November, 2011. The kit part number is the same as the attahced

picture.

Order from:

Then & Now

Automotive

447 Washington

St.

Weymouth, MA

02188

Tel. 781 335

8860

Disassembly of

these fuel pumps is tricky so I have made up a set of instructons, also

attached.

J. R. Ranney

(N6748K)"

I'm sure all you Franklin guys are happy to see this! Thanks JR! See a photo of the kit here. Also below: UPDATE! A few addiional

notes on the Franklin fuel pump thing:

It was Walter

Windus who discovered (or rediscovered) the source of the repair kits, not

me.

I've just been on

the phone with Rich Brumm. He said he's used these repair kits before and had

bad luck with them. In one case the end of the diaphragm plunger broke off, and

most of them start to leak after 100 hours or so. The kits he used did not have

the "-A" on the part number, so they might or might not be improved.

J. R.

Ranney

|

| First question by member Michael Alman (edited by S. Mestler).... What is the differences between the B8F and the B9F? Which is preferred? Can anyone discuss their experiences with either of these engines? Michael Alman, A&P/IA e-mail: boatflyer@hotmail.com 6/13/2010 |

Steinar Sevdal (Seabee Historian extrordinare) from Norway says... This is from my webpage; http://www.seabee.info/seabee_revisions.htm I am no expert (yes he is. SM)...this is just info I found in a variety of literature. Update! It comes form a very reliable source that the -B8F had a smaller gear drive for the magnetos that caused a few engine failures caused by this gear failure. Both mags quit and then, of course, the engine quits. He says the -B8F is very unreliable. Aircooled motors also changed the valve train system in the later -B9F. |

Looking for Original Fuel Pump Diaphragms... "My name is Tom Danaher and I own SeaBee S/N

150, N191VW. I purchased it in

1959 at Portage, Wisconsin. It is stock throughout. Still flys good with a B8F Franklin. I need

some fuel pump lower diaphragms. I have been making

them from stock neoprene sheet but they begin leaking in 30 or 40

hours. Can you

tell me of any source for these small (about 1-1/2") diaphragms?

Would appreciate your help very much. Thanks.

Tom Danaher TomDanaher@speednet.com |

Answer from Jim Poel...

Hi Tom. Congrats on the new

Bee. The diaphragms that you talk about sound smaller than the ones on

my Bee, but maybe not as I am not near the Bee right now. I bought

up a bunch of old carbs at an auto parts store some years ago and used

the diaphragms out of some of them, but there are probably not many of

those left. I would recommend Rich Brumm, brummrichkaren@aol.com

, who overhauls Franklins and their parts.

Good Luck. Jim Member J. R. Ranney aswers... Tom Danaher has an inquiry about material for Franklin fuel pump diaphragms. A company called Rubber Sheet Roll (info@rubbersheetroll.com) of Shippensburg, PA, has fablic reenforced neoprene available in 12" X 12" sheets .062 thick for $17.71. |

Looking for Autolite Manuals... Does

any franklin engine owner know where I can locate a parts manual,

overhaul manual, or sevice manual for the autolite distributor used on

the B-9F engine.?

Many Thanks,

Glen

Hyde cell: 214-546-8811 or E-mail: ghyde747@pwhome.com |

None yet... |

|

Looking for propeller or hub...

Hello fellow Seabee person(s), I'm hoping you may have

a

lead for me that would help get my vintage 1947 Seabee airborne again.

I have been grounded by that pesky Airworthiness directive on the

propeller. The blades are good but one clamp has a bit of

corrosion and I need at least a new clamp if not a replacement

propeller. I know many operating Seabees have had engine conversions to

newer Lycoming and other engines. I'm looking for those propellers and

clamps that were taken out of service when those new engines were

installed.

I have a

Franklin 215-B9F (215 HP) engine (standard

stock engine) in good running condition. The Seabee and engine are

completely operational. The prop blades are good as well.

However, the required AD procedure on the prop reveals a very minor

amount of corrosion on one of the propeller CLAMPS. If I

could get a single clamp, that would be perfect.

My clamps and prop blades are off in a prop shop so I can't

go and get all their numbers.

I'm also considering having a clamp made from scratch. I did that with my valve guides and, while I understand that a propeller clamp is much more complex and subject to tremendous stresses, it still might be a possibility. Maybe I can find someone who has done this "owner manufactured part" process..... Oh, yes...... I'm in Santa Cruz, California

I'd certainly appreciate any leads or suggestions you might

have or, if you have a serviceable prop clamp that fits my prop, or, if

you can locate one, we deffinitely can do business!

Thanks for anything you can do!

(831) 427-0836

6/19/2005 |

None yet... |

| Propeller control

adjustment... Hey there guys, just to let you know I am a aircraft maint engineer (canada) who has been restoring a seabee for an Air Canada pilot (Tom Stockdill) for the past 2 years (part time). I can't remember the serial number of hand but believe it to be around 1000. I've enjoyed working on this remarkable aircraft immensely, and we hope to have it flying in the summer (2003). This aircraft has not flown for 6 years and was in pretty rough shape when we started the re-construction. We had the original Franklin engine re-built, and have completed some upgrades; electronic fuel qty indication, VOR, replaced fuses with curcuit breakers, cleveland brakes, eng oil filtration system, etc. If you have any information in regards to the rigging of the prop control I would appreciate it as all the info I have on hand is pretty ambiguous. Regards, James Babcock 3/20/2003 |

Jim Poel

answers... Hello James, congratulations of bringing back another Bee. The Prop control is not that hard to adjust if the prop itself is set up properly from the prop shop. The stop for the prop control, (not the Reverser control), should be set to allow a static rpm of 2300 to 2350. This is done by having the reversing control against it's stop,(full forward), and adjusting the stop bolt for the main prop control. An easy way to do this is to set it high, do a full power run up using the prop control to limit the rpm to 2300, then after shutting down, adjust the stop to the position of the prop control. Once it is set, while running at 1000 rpm, SLOWLY move the reverse control back to full while someone watches from the side. If the clamps are not set properly, the bolt heads on the clamps will hit the valve when in full reverse. If this does happen, it is legal to grind a taper in the bolt head as long as long as you only grind the wrench grip portion, not the tapered shank. During the take off, the rpm will increase to over 2500 (red line) and it should be brought back down a couple of turns to the red line. This is just procedure for every take off. If you have any questions, Let me know. Good Luck! Jim Poel Ralph Buter writes:

I have some info on prop settings. Please give me your fax and I will send them to you. |

|

Propeller

for Franklin Engine...

John Atkins asks: I have been corresponding with a gentleman about a Seabee, turns out it has no prop. I see another Seabee on your web site for sale and owner can't get or afford a prop?! Question is, what prop(s) can go on the Seabee with the Franklin model 6A8-215-B8F engine, and what sort of price should one expect to have to pay ? Thanks, John Atkins 2/1/2003 |

Answer #1 from Jim Poel...

A new

Hartzell prop goes for around $15 or $16K. They are a different blade

and clamp design than the older Hartzell props and have no AD. There

are a number of "old design" props that are around for substantially

less money, but have the AD with them. The AD is a 5 year inspection,

and may require new clamps. I don't know if Hartzell still makes the

old clamps or not. The old props work just as well as the

new ones, (some say better due to the hardness of the blades).

Just be sure it passes the AD before you buy one. Also, Hartzell doesn't make the

hydraulic part of the prop anymore, piston, cylinder, valve, etc. They

only make new props down to the jack plate.

The good news is that there are usually a lot of hydraulic

parts around.

Good luck! Jim Poel |

|

Franklin Oil Filter...

(Ed note: Member J.R. Ranney asks about an oil filter for the Franklin Engine, please let me know so I can post it for everyone to use. S.M. for the IRSOC) Hi Steve, Does anyone else have a copy of the Form 337 for the oil filter installation,

not the Airwolf Lycoming one but the other.

Thanks.

J. R. Ranney: wranney@hotmail.com

|

None yet... |

| Franklin Cowl

Latches... (Tip from Jay Herte) Does anyone else have the problem of the cowl latches falling into the way as you try to close the cowl? 12/22/2002 |

My

solution is: A drop of super glue on the latch pin stiffens

up the movement just enough to keep them from falling in the way as I

close the cowl. Easy and inexpensive! I use the gap filling super glue and

kicker purchased from local hobby store.

Jay Herte Hi Jay,

That sounds like a good idea. Rich Brumm came up with a little spring that wraps around the pin and holds the latch up. That solved my problem. The springs are hardware store items. Installing them requires cutting the center portion of the latch that holds the pin to make room for the spring, then installing the spring so that it holds the latch up. Jim Poel |

Back to Top